R value to U Value calculator

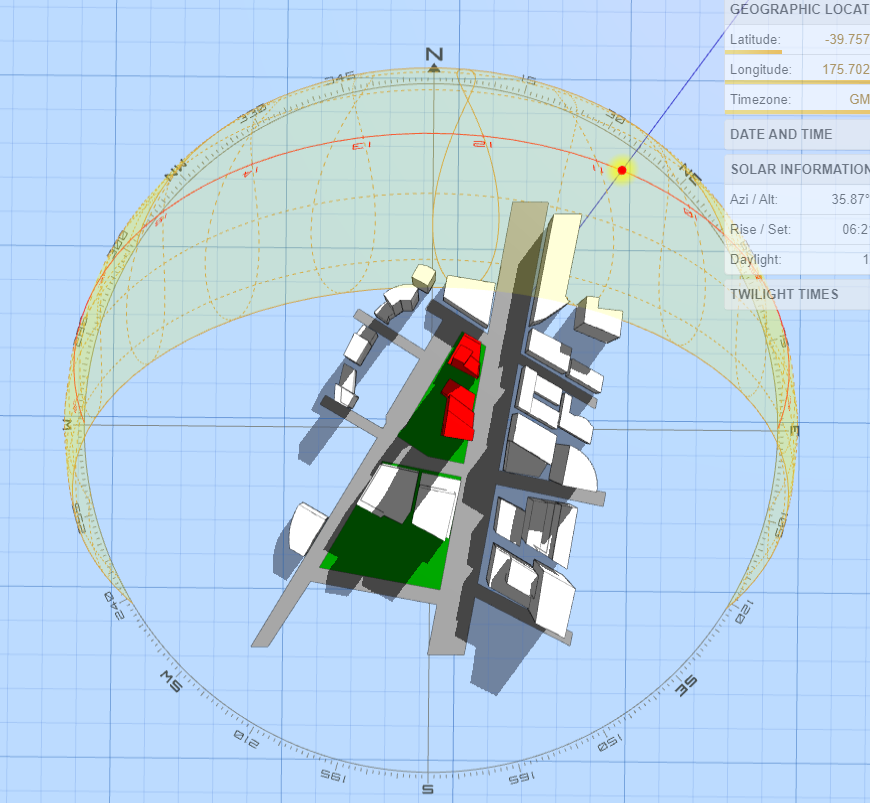

It is fundamental that the main living areas should be on the north, sunny side of the house. The windows in these living areas are most useful if they are orientated within 20 degrees of due north. Due north is actually to the west of compass north by approximately 20 degrees. Rooms which require early morning heating or afternoon coolness, e.g. the kitchen, should be orientated to the east, while spaces which are occupied in the evening should be located to the west. Bedrooms to the west for pre-heating prior to bed time. Office is East but no advantage as window faces north. South-West facing glazing should be kept to the minimum required for ventilation. (Master bathroom).

The addition of a sunspace can realise significant gains in energy efficiency. This can amount to around 30% when compared with a direct gain equivalent.

Thermal mass can be incorporated into any surface of the home but it is twice as effective if it receives direct sun rather than diffused rays. Exposing thermal mass products to heated air but not direct sunlight has little value in storing solar heat and should be minimised. The most effective depth of the material is the first 50 mm.

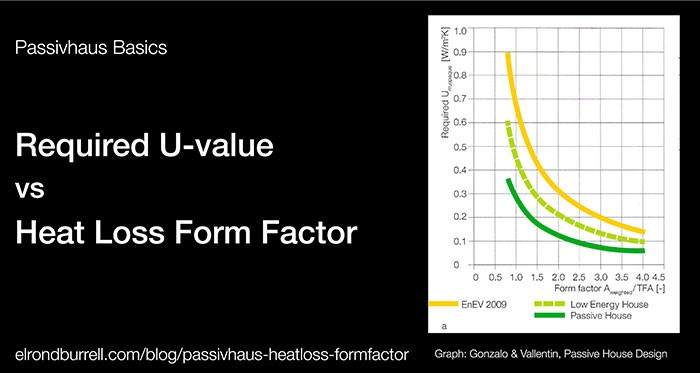

Heat Loss Form Factor = Heat Loss Area / Treated Floor Area (1.6). The Heat Loss Form Factor is a number generally between 0.5 and 5, with a lower number indicating a more compact building. Passivhaus buildings aim to achieve 3 or less. Once the Form Factor is over 3, achieving the Passivhaus Standard efficiently becomes noticeably more challenging.

Building Code H1/AS1 Calculation Method

A Passive House building will not use more than 15kW per square metre, per year for heating and cooling to the recommended indoor temperature as recommended by WHO, 18-21°C.

Air tightness <0.6 ACH with pressure differential of 50 pascal

Primary energy demand <120 Kw/h per sqm per year (20kW/Day)

Thermal bridge free

R6 walls, R9 ceiling

Rating tools such as Green Star, Home Star, the Infrastructure Sustainability rating or Greenroads

U-values

The heat losses though a standard building component, i.e. external wall (0.14), floor (0.32), top floor ceiling or roof (0.069), are defined by the U-value or overall heat transfer coefficient (formerly k-value). This value indicates the rate of heat transfer through a specific component over a given area if the temperature difference is one degree (1 Kelvin). The measurement unit of the U-value is therefore “W/(m²K)”. The smaller the U-value the better the level of insulation.

To calculate the heat loss through a wall, one must multiply the U-value with the area and temperature difference 2). In Central Europe, the average temperatures measured during severe winter periods are –12 °C outside and 21 °C inside.

To calculate the annual heating losses, one must multiply the U-value with the average temperature difference in the heating period with the duration of the heating period, or in other terms, multiply the U-value by the heating degree hours – which is 78,000 degree hours for an average Central European climate.

Using the example of a small single-family house with an external wall surface of 100 m², the following values were calculated for various U-values:

The heat loss is a significant factor in the energy balance of a building. Any heat loss must be compensated for by a corresponding heat gain, otherwise the temperature inside the house will drop.

A typical Passive House compact heating system can provide a heating power of about 1,000 W (that’s the typical output of a hair dryer). The U-value of a Passive House wall needs to be quite low; otherwise, a considerable portion of this power would be used up by the external wall: For typical Central European buildings, U-values of Passive House walls should range between 0.10 and 0.15 W/(m²K); depending on the climate, these figures may be somewhat higher or lower.

Insulation Requirements

NZ Building code.

• Zone 1 is Far North

• Zone 2 Napier

• Zone 3 Palmerston North

• Zone 4 Wellington

Building Code H1/AS1 Calculation Method

12kW heater required. Based on YouTube – 1.5kW. Depends if it is per day or per hour. 12kW for 10-12 hours a day would make 12kW correct.

Heat recovery systems provide good fresh air ventilation but they are not a heating system. However, they can recover between 67–95 per cent of the heat from the inside air. Recycle hot air from ceiling areas down to floor level. Thermostatically controlled.

Increasing ceiling, windows or walls does little

Usual build cost: Around $3500 per square metre.

- Builder: Thomas Lynch, Artisan Developments

- Architectural designer: Erik Nielsen, Cadviz

- Ecowindows – Bjorn & Thomas (Windows and Ventilations Systems)

- Proclima Airtightness – Sheets under the insulation, airtightness tapes

- Ecodure flooring – Coretec luxury vinyl tiles

- Kingspan Insulation

- Harrisons Solar

- Hamish Stirrat of Fabricate Architecture

“80% reduction in total power consumption, Kingspan K17 insulated panels (Insulated Dry-lining Plasterboard for Adhesive Bonding). We added another (thermal) barrier to the exterior walls – a layer of plywood – and we have two insulation layers. Pink Batts line the walls, and then the 7mm plywood layer was laid over this, followed by the 50mm-thick Kingspan insulation.

When winter temperatures fell below 0 degrees, we tested the early morning temperature and compared it to our first project. It was 12 degrees in the minor dwelling, as opposed to 15 degrees in our full Passive House. These results were recorded without any electric heating used during the night.

Coretec luxury vinyl tiles from Ecodore Flooring were specified for the floor, providing double the normal insulation underfloor to match insulation in the ceilings and walls. These tiles consist of a cork base, PVC core and a vinyl top layer.”

stuff.co.nz/life-style/homed/latest/129354862/passive-housestyle-benefits-for-30-less-than-the-cost-of-a-new-certified-build

Say a 6-degree delta, so a 3Kw heat pump, for 2 hours in the morning and 6 hours in the evening. 8 hours, 240w heat loss per hour per degree = 1.92kW divided by Coefficient of efficiency (4) = 500W per day of electricity required. BUT, Ventilation loses some, though 65% is recovered by the MHRV, so 1.2kW per day.

• Underfloor R5

• Wall R3

• Ceiling R6.6

• Double glazed (including warm edge spacer), thermal break, 3M film and secondary glass = 0.8 + 0.44 + 0.19 = R1.43

10-15% heat loss through floor (80% of that is through the perimeter), 20-30% through walls, 20–30% through the window, 30-35% through ceiling

Geometric features cause thermal bridging.

Passive House

A highly respected international standard for green buildings is Passive House, sometimes known as Passivhaus. A Passive House requires little or no mechanical heating or cooling and remains healthy and comfortable year-round.

To achieve this, the thermal envelope of the building is paid special attention. Any gaps where hot air could escape and cold air could replace it are rigorously found and removed. What results is a home with an airtight seal, where the air inside can be kept warm easily.

Other design elements like north facing windows to take advantage of sun, as well as materials with high thermal mass such as concrete floors help Passive Houses achieve their low energy requirements.

The Standard

• Space heating: less than 15 kWh/m2/yr, or requiring a peak heating load of 10 W/m²

• Total primary energy use (heating, hot water and electricity): no more than 120 kWh/m2/yr

• Air leakage: no more than 0.75 m3/m2hr @ 50 Pa (0.6 air changes per hour)

• The specific heat load for the heating source at the desired temperature is recommended, but not required, to be less than 10 W/m2

• Triple-glazed advanced window technology. Glazing and frames combined should have a U-value of not more than 0.8 W/(m2K).

• The ‘G-Value’ measures the degree to which glazing blocks heat from sunlight. The G-value is the fraction of the heat from the sun that enters through a window. G-value is expressed as a number between 0 and 1. The lower a glazing’s G-value, the less solar heat it transmits.

R-value Listing of Common Products

These are Generalised R-value numbers for many types of building materials. These values may not be accurate for your building material. Consult your manufacturer for more accurate data if required.

| MATERIAL | THICKNESS | M2K/W | R-Value |

| Air Film Exterior | 0.04 | 4.25 | |

| Air Gap | 1.2cm – 10cm | 0.176 | 0.97 |

| Chipboard | 18mm | 0.17 | 1.00 |

| Plywood | 25mm | 0.22 | 0.77 |

| Timber | 25mm | .12 – .25 | 0.00 |

| Cement Sheet | 8mm | 0.5 | 0.34 |

| Polyurethane foam-a-fill | 25mm | 1.1 | 0.15 |

| Air Film Exterior | 0.04 | 4.25 | |

| Polystyrene | 25mm | 0.88 | 0.19 |

| Common Brick | 90mm | .05 – .07 | 0.00 |

| Concrete | 100mm | 0.86 | 0.20 |

| Glass | 6mm | 0.9 | 0.19 |

| Rubber | 3mm | 0.009 | 18.90 |

| Hardwood | 0.12 | 1.42 | |

| Tiles | 0.9 | 0.19 | |

| Solid Core Door | 44mm | 0.38 | 0.45 |

| Single Pane window | 6mm Glass | 0.9 | 0.19 |

| Double Glazed 4mm glass | 6mm gap | 0.5 | 0.34 |

| Double Glazed 6mm glass | 6mm gap | 0.32 | 0.53 |

| Double Glazed 4mm glass | 12mm gap | 0.47 | 0.36 |

| Double Glazed 4mm glass | 16mm gap | 0.37 | 0.46 |

| Double glazed 4mm – 4mm | 20mm gap | 0.36 | 0.47 |

| Double glazed 4mm- 4mm | 30mm gap | 0.358 | 0.48 |

| Triple Glazing 4mm glass | 6mm gap | 0.46 | 0.37 |

| Triple Glazing 4mm glass | 12mm gap | 0.56 | 0.30 |

| Double Glazing low-e 6mm and internal 4mm | 12mm gap | 0.58 | 0.29 |

| Triple Glazing 4mm glass with low-e | 12mm gap | 0.82 | 0.21 |

| Double glazed 4mm – 4mm – low-e | 10mm gap | 0.55 | 0.31 |

| Double glazed 6mm – 4mm – low-e | 10mm gap | 0.55 | 0.31 |

| High Performance Laminate Glass + Low-E | 8.37mm | 0.29 | 0.59 |

| Poor Performance Laminate Glass- no Low-E | 6mm | 0.175 | 0.97 |

| Spray Foam Closed Cell | 100mm | 4.8 | 0.04 |

| Spray Foam Open Cell | 100mm | 2.64 | 0.06 |

| Suntuf Twin Wall Polycarbonate Corflute | 10mm | 0.34 | 0.50 |

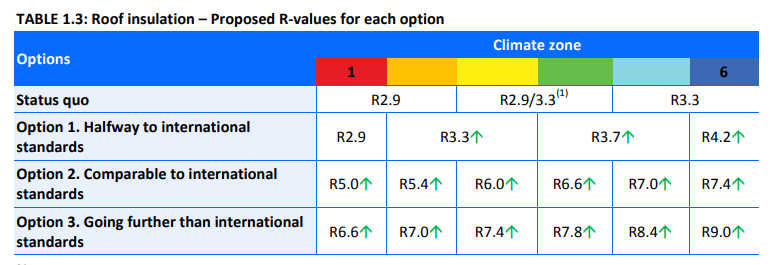

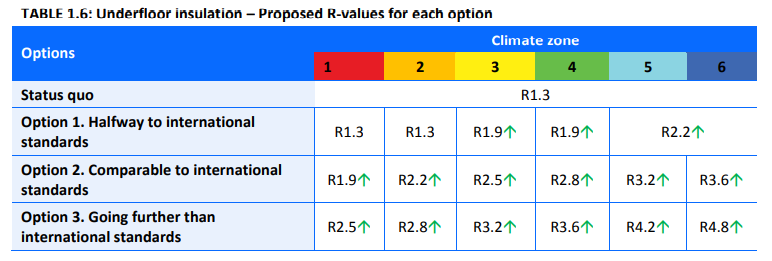

Minimum R values from May 2023

LEED

LEED stands for Leadership in Energy and Environmental Design, and it takes environmentally-sound building practices into account.

The U.S. Green Building Council (USGBC) assigns a score based on certain factors, including energy and water usage, the quality of indoor environments, the selection of materials, and the overall site effects.

If a project receives a certain score, the USGBC will confer a basic certification, or a silver, gold, or platinum ranking. Evaluators base the decisions on how well these eco-friendly factors are taken into consideration.

LEED Certification tells customers and employees that you have been intentional about lowering the carbon footprint of your new or renovated structure.

After two-plus decades, LEED is still widely recognized as the most important green building standard in the industry. Buildings with LEED certification can qualify for tax breaks, government grants, and expedited permitting (in some cases).

What is LEED Certification?

USGBC was formed in 1993 as a group of architects interested in creating a rating system for projects that take environmental responsibility seriously. They spent the next five years developing a coalition of trade groups and supporters that committed to voluntary eco-friendly building practices.

The organization serves as a neutral third party to verify if a building or larger project utilizes environmental strategies. In addition, the LEED process is meant to encourage a mutual relationship between architects, design firms, engineers, contractors, and others throughout the design and build phases.

When USGBC unveiled its first iteration of LEED in 1998, it had several goals in mind:

• Lower construction and renovation work’s effect on climate change

• Create buildings that contribute to the health of individuals who work, live, or visit there

• Safeguard the supply of water, biodiversity, and ecosystems

• Utilize sustainable and renewable resources

• Improve the neighborhood’s quality of life

Since the initial test launch in 1998 and subsequent public launch two years later, the USGBC has improved and updated LEED several times.

Updates include a science-based rating system in 2009, a smart-grid approach in 2015, and new algorithms and methodologies in 2019.

By 2010, the USGBC certified 5,000 projects throughout the U.S.

Today, existing and new construction projects can work to achieve LEED v4.1, the most comprehensive certification to date. Projects that opt to shoot for LEED Certification should be ready to address several goals, including building a greener economy and enhancing environmental justice and social equity.

LEED evaluators look at each project’s design and assign point values based on quantitative and qualitative analysis. For example, intended carbon dioxide levels can be measured in parts per million.

On the other hand, assessing a “strong sense of place” is more ambiguous.

The organization admits that scoring a project is often complicated and subjective.

Main LEED Certification Categories

The UDGBC has identified seven impact categories they use to determine if a project will qualify for LEED certification. Each impact category carries a weighted score based on its environmental impact. The impact categories are:

• Reverse Contribution to Global Climate Change (35%)

• Enhance Individual Human Health and Well-being (20%)

• Protect and Restore Water Resources (15%)

• Protect, Enhance, and Restore Biodiversity and Ecosystem Services (10%)

• Promote Sustainable and Regenerative Material Resource Cycles (10%)

• Build a Greener Economy (5%)

• Enhance Social Equity, Environmental Justice, and Community Quality of Life (5%)

Each impact category is broken down into several sub-categories to gain the overall score. Sub-categories include the protection of natural hydrological cycles, habitat protection, reduction of raw material extraction, and strengthening the green industry supply chain.

Projects are scored on a 100-point scale. Developers must consider all seven impact categories tangibly for a project to qualify. Projects then earn extra points as they pay more attention to various sub-categories.

A project must score at least 40 points to earn certification.

• LEED Certification – 40-49 points

• LEED Silver Certification – 50-59 points

• LEED Gold Certification – 60-79 points

• LEED Platinum Certification – 80+ points

How Can I Get My Building LEED Certified?

The LEED certification process is broken down into four steps:

Register the project. This includes completing forms and submitting payment. Fees range depending on the building/project size. New construction starts at $2,325 for members of the organization and $2,740 for nonmembers. Prices go up considerably once the project exceeds 250,000 square feet.

Apply for certification. There are more forms and payments to make.

LEED Review. This is the process whereby the USGBC looks over your project and compares it to the seven impact categories mentioned above. It usually takes about 20 to 25 business days for USGBC to score the project. You can ask for an expedited review (as little as 10 days) for an extra $10,000.

Certification. After the review, the USGBC will send its determination. Those who do not receive the 40-point minimum for certification, or wish a more exclusive rating, may appeal.

6 LEED building certification rating systems

The USGBC has developed LEED certifications for six different project types. These include new commercial buildings, new interiors, new homes, and new neighborhoods.

Building Design and Construction

Developers of healthcare facilities, schools, banks, distribution centers, or data centers can apply for LEED certification. Additionally, designers of multifamily residential projects may use the BD+C option if their project is at least four stories high. Hotels, motels, and other types of short-term or transitional lodging projects are also eligible.

USGBC evaluators will look over the planned construction of new buildings or major renovations. They will specifically pay attention to and grade the following:

• Planned greenhouse gas emissions

• Building materials and resources

• The amount of daylight expected in the building

• The amount of noise limiting structures

• Rainwater management

• Interior Design and Construction

Project teams who work on a building’s inside but exercise no control over its exterior can apply for the ID+C certification. These are built for commercial functions, retail spaces, or the hospitality sector.

USGBC evaluators will focus much of its score on the following criteria:

• Ensuring that smoking is prohibited throughout the space

• Further Improvements to indoor air quality and ventilation systems

• Daylight exposure

• Acoustic limitations

Operations and Maintenance

USGBC says it takes up to 80 years to realize environmental efficiencies when one building is demolished and another one is built in its place. So, they specifically designed the O+M certification for buildings that have been occupied for at least a year and undergoing renovation.

Evaluators will key on the following:

• Refrigeration management

• The use of green cleaning products

• Pest control

• Occupant satisfaction surveys

Residential

The latest LEED certifications also include new home construction. Developers of single-family homes in a new subdivision may volunteer to qualify. So can developers of a new apartment or condominium complex. Major renovations to existing structures may also become LEED certified.

Evaluators expect new construction to avoid floodplains, prevent pollution during the build, and use tropical woods. They will give extra points for several planned efficiencies, including:

• Waste management techniques

• Radon resistance

• Hot water distribution

• Housing density of at least seven units per acre

Green Star

Green building ratings are not limited to residential houses; commercial and multi-unit builds have specially designed sustainability and energy-use certifications too.

The primary example of this in New Zealand is the Green Star Rating. Like Homestar, it’s managed by the New Zealand Green Building Council, and assesses the green credentials of buildings across nine categories: energy, water, materials, indoor environment quality, transport, land use and ecology, management, emissions, and innovation.

CodeMarkTM

CodeMark is the only deemed to comply product certification scheme in Aotearoa New Zealand that shows a building product or method meets the requirements of the Building Code. Building consent authorities must accept a CodeMark certified product as complying with the New Zealand Building Code when it is used in building work, as long as the product is specified for use in accordance with the product certificate. To apply for CodeMark, you need to contact an accredited and registered Product Certification Body (PCB). You will need to supply technical evidence detailing how your building method or product complies with the Building Code. If successful, you’ll get a CodeMark product certificate that, once registered by MBIE, shows your product is compliant with the New Zealand Building Code. The current fee for registering a CodeMark Certificate with MBIE is NZD $180.30 (excluding GST). MBIE will issue you with an invoice for this fee. Bureauveritas Certification

The Living Building Challenge

The international green building standard that’s considered by many to be the most stringent and comprehensive is the Living Building Challenge (LBC).

The premise is simple: buildings should be part of the environment in a way that allows them to be as close to self-sufficient as possible, harming little of their surroundings. The central metaphor the LBC operates from is that of a flower—an addition to the environment that functions cleanly and efficiently and doesn’t harm its environment.

This is achieved by designing buildings that are net-positive—that is, creating more than they use—in terms of energy generation, water supply and waste.

The flower metaphor extends to the way the LBC determines whether a building is eligible for certification. There are seven petals or performance areas within which specific targets must be met: place, water, energy, health + happiness, materials, equity, and beauty.

LBC buildings must be free from any products on the Red List, a catalogue of worst-in-class building materials that contain chemicals harmful to the environment, wildlife, and people. Living buildings must also use locally sourced materials from within a specified radius of the building site.

Lifemark® Standards

A new home design is rated against the Lifemark® Standards and awarded points based on how adaptable, safe and usable the home is. The better the rating (3, 4 or 5 Stars), the more it will suit your family’s needs throughout life as they change.

Homes will be assessed focusing on suitability in the following areas:

• Access to the home – pathways and entrances

• Getting around – doorways

• Fittings and fixtures – light switches, handles and tap ware

• Bedrooms

• Kitchen and Laundry

• Bathrooms

At a gala event in London last month, Lifemark® was recognised as the best in the world when it comes to Universal Design innovation.

Universal Design is that all people have differing abilities and needs when using the environment and to create a positive experience for the building user. These diverse needs can be accommodated if the approach to design is comprehensive and inclusive and does not cater for specific disabilities. BarrierFree has advocated for the creation of ‘Barrier Free’ environments

Habitat for Humanity Co-housing Development

The organisation finds land, gets skilled builders and volunteers to build a house, selects a family in housing need who move into the house and pay rent until they are in the position to access third-party finance to enable them to buy it.

Rent is set at a manageable level and when the family are in a position to purchase the home, the rent paid is given back to them for a deposit.

Universal Design

Accessible design, lifetime design and futureproofing all describe similar design concepts that involve:

• making buildings safer and easier to use for everyone all of the time – this is all people of

all abilities at any stage of life, including young children and people with limited mobility, temporary injuries or permanent disabilities designing new homes so they accommodate the changing needs of people as they age.

• Universal design features allow people to continue to live independently in their own home as they age, regardless of their physical ability, health or age.

In essence, universal design is inclusive design.

NZ lags in universal design. Most New Zealand homes do not incorporate universal design principles or provide good accessibility for people with physical disabilities. As a result, significant and often costly modification can be required where the needs of occupants change. The current shortage of these properties will only get worse as the population ages.

Narrow door openings, long narrow hallways, small rooms and spaces, indirect or convoluted travel paths within the building and stairs can make moving around the home difficult for young children, older people and people with limited mobility.

In our many hillside suburbs, steps provide the only access to the house, making simply getting to and from the home difficult for anyone with impaired movement.

A 2016 study (see BRANZ External Research Report ER19) found a deep lack of awareness of universal design in the building industry to the extent that there was an ‘apparent inability to access universal design from the building industry even when it is desired and explicitly sought by householders’.

The study also found the rewards for householders who do achieve universal design dwellings included ‘considerable satisfaction across a number of functional and comfort dimensions’.

Acceptable Solution D1/AS1 gives specific requirements on the design and detailing of access

routes, ramps, stairs and handrails. Design information on universal design is also given in:

- NZS 4121: 2001 Design for access and mobility – Buildings and associated facilities

- AS 4586-2013 Slip resistance classification of new pedestrian surface materials

- www.aucklanddesignmanual.co.nz/design-thinking/universal_design

- www.branz.co.nz/universal_design

Although it is often forgotten, children and older people have many of the same housing performance and design needs. For instance, both children and older people are more vulnerable when indoor temperatures drop below 16°C, often referred to as the World Health Organization standard.

Examples where functionality is improved without the need for additional area include:

• designs that utilise spaces for multiple functions (corridors that also have storage) or avoiding corridors completely

• locating the kitchen immediately adjacent to the main entry or the access point onto the dwelling from an attached garage

• utilising open planning – fewer walls or definition of spaces

Key universal design features. Some building features are considered an essential part of universal design. These are summarised below and expanded on later in this supplement.

The basic principles of universal design include:

• having flat or ramped access to the main entrance with no steps between the street and the dwelling entry

• a covered sheltered entry porch

• having the main floor at entry level

• having the kitchen, bathroom and at least one sleeping area at entry level (the sleeping area could also be used as a study or living area)

• avoiding long (narrow) corridors and sharp turns into adjacent spaces.

• ensuring all rooms are large enough for residents to easily move around in once furnished

• ensuring all walkways and doorways are wide enough for strollers, wheelchairs or mobility scooters to easily pass through (while a 800 mm-wide doorway will allow minimum clearance for wheelchairs, specifying 910 mm wide doors as a minimum is prudent)

• ensuring garages and carports are large enough for wheelchair access into and out of vehicles.

For kitchen areas:

• providing a mix of kitchen bench heights and other work/storage spaces – consider at least one lower bench or one that is height adjustable

• locating appliances at a height that is reachable from a wheelchair and sufficiently above the floor to reduce bending or kneeling

For bathroom areas:

• installing doors opening outwards (resist any request to put locks on bathroom doors)

• providing grab bars beside toilets and within the shower

• providing a wet area or European shower (a shower that drains directly through the floor with no door or ‘lip’ that has to be stepped over).

For switches and handles:

• using lever style door handles (which are easier to grip and open than door knobs)

• having light switches, socket outlets and door handles at easily reached heights

• installing light switches at all entry points into spaces – for bedrooms, have the second switch located by the bed and at the other end for corridors

• providing a telephone outlet by the main bed.

Examples that are flexible for all ages

• the garage and entry have direct access to the kitchen

• corridors have been eliminated

• the kitchen is centralised and accessible

• one bathroom is accessible and en-suite.

Covered entry

Provide shelter to the entry door by a recessed porch or a canopy. Wheelchair users are likely to have the door open for a longer time than ambulant users. Ensure the entry is well lit at night preferably with a sensor-operated light and has enough manoeuvring room for a wheelchair. A seat or parcel shelf is useful to include.

Accessible mailboxes

Locate the mailbox so a driver can pick up the contents through the car window and a wheelchair user or ambulant person has easy access.

NZ Government Announcements

Proposals – set to begin in 2024:

Offices must be upfront about how energy efficient they are – or aren’t – under new green building rules announced by the Government. Avoiding construction materials headed to landfill, large building projects must also create a waste minimisation plan.

The rules will apply to commercial, public, industrial and residential apartment buildings larger than a yet-to-be-determined size, according to the Ministry of Business, Innovation and Employment.

Stand-alone homes won’t need an energy rating – though a ministry spokesperson said the Government “may consider” introducing a similar requirement at a later date.

NZ’s Green Building Council (Chief executive Andrew Eagles), which administers energy efficiency assessments for commercial properties

Australia has mandatory energy efficiency ratings for commercial buildings, a system known as NABERS.

Nearly 100 buildings are currently rated under the New Zealand version of NABERS. In total, 390 premises have been assessed since the system were licenced by the Energy Efficiency and Conservation Authority.

Individual home builders won’t be required to submit a waste plan to council, the ministry said. But the rules are set to apply to subdivisions and developments as well as commercial building projects.

Energy Modelling

Energy modelling software such as the Passive House Planning Package (PHPP) uses set points for internal conditions (between 20 and 25 degrees) and then calculates the energy required to maintain this healthy and comfortable condition for the whole year. The new Energy and Carbon Calculator for Homes (ECCHO) created for Homestar v5 uses PHPP as the base calculation method. The maximum allowable heating demand for Passive House is 15 kWh/m2/yr, which also happens to be the end cap for New Zealand’s proposed Building for Climate Change framework, and the threshold for achieving maximum points in the new HC1: Winter Comfort credit of Homestar v5.

Where there is good solar access and exposed concrete floors to provide thermal mass, north-facing windows should be approximately 10-15% of total floor area. With timber floors, north-facing windows should be closer to 10% of floor area. Where solar access is poor, the north-facing windows should be less than 8% of floor area.

Glazing that is east, west or south-facing should be smaller and designed mainly to meet daylight and view requirements. This glazing is usually a net heat loser in winter, depending on climate and heating.

East-facing windows should be reasonably small – less than 5% of the home’s total floor area.

South and west-facing windows should ideally be less than 3% of floor area and be designed for daylight, views and cooling cross-flow breezes in summer.

Dynamic 3D Sun-path visualizer

Plan roof openings and north facing windows to fit the winter sun and shade summer sun. 40o and 20o

Thermal mass in direct sunlight should be 3x the window area.

The expected modelling time (in hours) for a house of low complexity is provided to allow comparison.

AccuRate was developed by CSIRO (Australia’s national science agency). AccurateNZ is the New Zealand version of the software. Batch processing, where multiple variables are looked at simultaneously, is possible using a free companion program called AccuBatch. AccuRateNZ is fairly user-friendly and only needs a modest one-off license to operate. However, the NZ version has not been updated for several years. It is a very robust calculation engine. [3.5 hours].

SUNREL software was developed by NREL (a national laboratory of the US Department of Energy). It is quite flexible in the passive technologies it can model and includes algorithms for Trombe walls and programmable window shading. It is free to use but requires skill to use as the user interface is primitive. It is a very robust engine. [4 hours]

IES-VE for architects is produced by Integrated Environmental Solutions, a Scottish-based company that specializes in software programmes for designers and engineers. It has an easy-to-use interface but requires some learning. It is interoperable with many graphics-based interfaces, such as Sketchup, Revit and VectorWorks. It is comparatively costly. There are several packages to suit varied users. It is a robust engine. [3 hours]

SEFAIRA is a London-based company that specializes in software programmes for building designers. It was one of the first simulation companies to make use of cloud computing, rather than having a stand-alone program that users access. It is a very robust engine, the interface is very easy to use and there are useful and comprehensive results built in. It is highly interoperable with design packages. Sefaira is especially good for comparing options and optimization. It is comparatively costly. [2.5 hours]

BRANZ ALF Can demonstrate compliance with Building Code clause H1.3.2E (“Buildings must be constructed to ensure that their building performance index does not exceed 1.55.”)

However, from 3 November 2022, an ALF calculation alone will not be enough to show that a house complies with all the requirements of Building Code clause H1.

HeatCAD 2022 is a drawing-based software for fast and accurate calculation of residential heating and cooling loads.

Estimating home heat loss, including R values of materials, infiltration loses, and the thermal performance of real walls.Simulation software to estimate the thermal performance of a passive solar or conventional home.

builditsolar.com/References/Calculators/HeatLossOld/HeatLoss

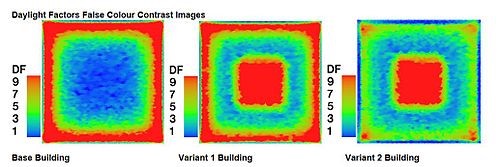

Daylight Factor

In architecture, a daylight factor (DF) is the ratio of the light level inside a structure to the light level outside the structure. It is defined as:

DF = (Ei / Eo) x 100%

where, Ei = illuminance due to daylight at a point on the indoors working plane, Eo = simultaneous outdoor illuminance on a horizontal plane from an unobstructed hemisphere of overcast sky.

To calculate Ei, requires knowing the amount of outside light received inside of a building. Light can reach a room via through a glazed window, rooflight, or other aperture via three paths:

• Direct light from a patch of sky visible at the point considered, known as the sky component (SC),

• Light reflected from an exterior surface and then reaching the point considered, known as the externally reflected component (ERC),

• Light entering through the window but reaching the point only after reflection from an internal surface, known as the internally reflected component (IRC).

The sum of the three components gives the illuminance level (typically measured in lux) at the point considered:

Illuminance = SC + ERC + IRC

The daylight factor can be improved by increasing SC (for example placing a window so it “sees” more of the sky rather than adjacent buildings), increasing ERC (for example by painting surrounding buildings white), increasing IRC (for example by using light colours for room surfaces). In most rooms, the ceiling and floor are a fixed colour, and much of the walls are covered by furnishings. This gives less flexibility in changing the daylight factor by using different wall colours than might be expected[2] meaning changing SC is often the key to good daylight design.

A study of daylight factors within a single storey building resulting from different perimeter glazing and rooflight designs and glass types. Undertaken using the IES Radiance software Module.

Architects and engineers use daylight factors in architecture and building design to assess the internal natural lighting levels as perceived on working planes or surfaces. They use this information to determine if light is sufficient for occupants to carry out normal activities. The design day for daylight factor calculations is based on the standard CIE overcast Sky for 21 September at 12:00pm, and where the Ground Ambient light level is 11921 Lux. CIE being the Commission Internationale de l´Eclairage, or International Commission on Illumination.

Calculating daylight factors requires complex repetition of calculations and thus is generally undertaken using a complex software product such as Radiance. This is a suite of tools for performing lighting simulation, which includes a renderer as well as many other tools for measuring simulated light levels. It uses ray tracing to perform all lighting calculations. One failing in many of these calculations is that they are often completed without wall hangings or furniture against the walls. This can lead to higher predictions of the daylight factor than is correct.

To assess the effect of a poor or good daylight factor, one might compare the results for a given calculation against published design guidance. In the UK this is likely to be CIBSE Lighting Guide 10 (LG10-1999), which broadly bands average daylight factors into the following categories:[4]

• Under 2 – Not adequately lit – artificial lighting is required all of the time

• Over 5 – Well lit – artificial lighting generally not required, except at dawn and dusk – but glare and solar gain may cause problems