Tiles

Concrete tiles need constant sealing and are not stain resistant. Clay or porcelain tiles required for high traffic areas.

Accessories

Vacuum cleaner

Godfreys.co.nz/work-hero-10l-dry-canister-plastic

GFRC – General

50Kg/ m3 at 25mm thickness – a 5.4m x 600mm x19mm panel weighs 130Kg

Most GFRC projects can be demolded in 24 hours.

concretecountertopinstitute.com

GFRC gets its strength from a high volume of alkaline-resistant (AR) glass fibers. The glass is treated with zirconia to resist the highly alkaline environment inside concrete. Durability has been increased through the use of low alkaline cements and pozzolans.

GRC Properties

Shrinkage / Swelling 1 mm/m

Weight 2000Kg/ m3 or 20Kg/sqm

Mix Calculator:

concretecountertopinstitute.com/shop/gfrc-calculator-electronic/

Fine Sand– Sand used in GFRC should have an average size passing a #50 sieve to #30 sieve (0.3 mm to 0.6mm). Finer sand tends to inhibit flowability while coarser material tends to run off of vertical sections and bounce back when being sprayed.

Cement– Typical proportions use equal parts by weight of sand and cement.

Polymer– Acrylic polymer is typically preferred over EVA or SBR polymers for GFRC. Acrylic is non-re-wettable, so once it dries out it won’t soften or dissolve, nor will it yellow from exposure to sunlight. Most acrylic polymers used in GFRC have solids content ranging from 46% to over 50%. Polymer dose is typically 6% solids by weight of cementitious material. Consider trying Forton VF-774, a reliable acrylic polymer choice.

Water– Common water to cement ratios range from .3 to .35. When determining how much water to use make sure to take the water content from your acrylic polymer into account. This can make calculating water to cement ratios difficult unless the solids content of the polymer is known. With a polymer solids content of 46%, 15 lbs of polymer plus 23 lbs of water are added for every 100 lbs of cement.

Alkali Resistant Glass Fibers– Fibers are an essential component of GFRC. If you’re using the spray-up method for casting the fibers will be cut and added to the mix automatically by your sprayer at the time of application. If you’re using premix or the hybrid method for casting you’ll mix the fibers in yourself.

Fiber Content- Fiber content varies but is typically between 3% to 7% of the overall cementitious weight. Higher fiber content increases strength but decreases workability. Unlike most concrete mix design ingredients, fibers in GFRC are not calculated as a percentage of dry cementitious weight. Instead, they are calculated as a proportion of total weight. This makes the math to calculate fiber load in GFRC mix designs quite complicated.

Other Admixtures– Some other elements you may choose to include in your mix include pozzolans (such as silica fume, metakaolin or VCAS) and superplasticizers.

Method

Creating GFRC is using a hybrid method that uses an inexpensive hopper gun to apply the face coat and a hand packed or poured backer mix. A thin face without fibers (called a mist coat or face coat) is sprayed into the molds and the backer mix is then packed in by hand or poured in much like ordinary concrete.

This is the method that most concrete countertop makers use.

This is an affordable way to get started. However, it is critical to carefully create both the face mix and backer mix to ensure similar consistency and makeup, and to know when to apply the backer coat so that it adheres properly to the thin mist coat but doesn’t tear it.

The high polymer content of GFRC means that long term moist curing is unnecessary. Cover a freshly cast piece with plastic overnight. This could be shorter if it has gained enough strength to be uncovered and processed. Many pieces are stripped 16 to 24 hours after casting.

Typical concrete countertops made with GFRC range from ¾” to 1” in thickness. This is the minimum thickness that a long, flat countertop can be made so it doesn’t break when handled or transported. Smaller wall tiles can be much thinner.

The face coat is allowed to stiffen until the surface loses some of its wet sheen. Plastic sheeting is placed over the back of the panel. The plastic prevents excessive moisture loss and maintains heat of hydration to ensure a proper initial cure. The panel is allowed to cure for 12-16 hours. All panels are allowed to cure for 7 days.

View our FREE, 2.5 hour seminar “Step by Step GFRC with Mix Design” by requesting access here. concretecounter.infusionsoft.com/app/page/gfrc-free-seminar

Test concrete for moisture using a piece of paper laid on top for 1 hour before applying 4 coats of sealer

Maximum thickness 15mm

Shower and kitchen, toilet gutter could be GRC with step to support stainless grate

4 coats of sealer – No nail polish, scouring pads or bleach – WARNING for laundry!

Concrete embeds

DECORATIVE AGGREGATE – BLACK GLASS

Sale price$42.09

expressions-ltd.com/products/decorative-aggregate-black-glass

GLOW IN THE DARK GLASS AGGREGATE ROCKS/SAND, PHOTOLUMINESCENT 1/2 LB.

Sale price$19.09

expressions-ltd.com/products/glow-in-the-dark-rocks-photoluminescent

Training – Buddy Rhodes buddyrhodes.com/information/buddy-rhodes-videos

Equipment

Polyurethane and silicone mold rubbers

Hopper gun

expressions-ltd.com/products/gfrc-spray-gun-hopper-sharpshooter-2-0

Sealer gun

expressions-ltd.com/products/hvlp-gravity-feed-spray-gun

Sink Moulds

expressions-ltd.com/collections/fiberglass-concrete-sink-molds-bathroom-drain

Buy polyurethane moulds for countertop edge (See here), make copies (Cast an edge 5m long, remove original, pour in polyurethane to make a copy. Cut into ‘Brick’ lengths (random) and arrange into 1m long paired strips of unequal length for casting. For panels, arrange multiple strips inside bigger form, reassemble (pairs of) strips in different order after each use of the mould. Mitre corners, rebate to cover tile edges etc.

Concrete Counter Tops

Decocrete:

Pour on Casting System

concretecountertopsolutions.com/collections/z-liqui-crete-system

Mould System

Do not cut on the surface or put hot pots on it. Use cutting boards and trivets.

FISHSTONE CONCRETE concretecountertopsupply.com

- HP50 concrete mix: bit.ly/2YL4MFA

- Acrylic Polymer: bit.ly/2SRQQHk

- Alkali Resistant (AR) glass fibers: amzn.to/31y6kEe

- Cake Fondant Tool for perfect edges: amzn.to/2w0JCVx

- Helical Mixing Paddle: amzn.to/2GFyxjF

- Concrete mixer: amzn.to/2kEnZFi

- Concrete pigments: bit.ly/2GxzWrf

- 1-part concrete sealer: amzn.to/2xW7Gth

- Black 100% Silicone Caulk: amzn.to/2B64iRY

- Paste Finishing Wax: amzn.to/2kF565e

- “From Scratch” GFRC Recipes: goo.gl/35RvFM

- Carbon Fiber Reinforcing Grids concretecountertopsupply.com/Item/Cgrid

Equipment

GFRC Backer coat sprayer for small to mid sized jobs $495USD

Kraft PC401 Gun & Hopper $138USD

Moulds

concretecountertopsolutions.com/collections/form-liners

2.4m x 31mm $59USD

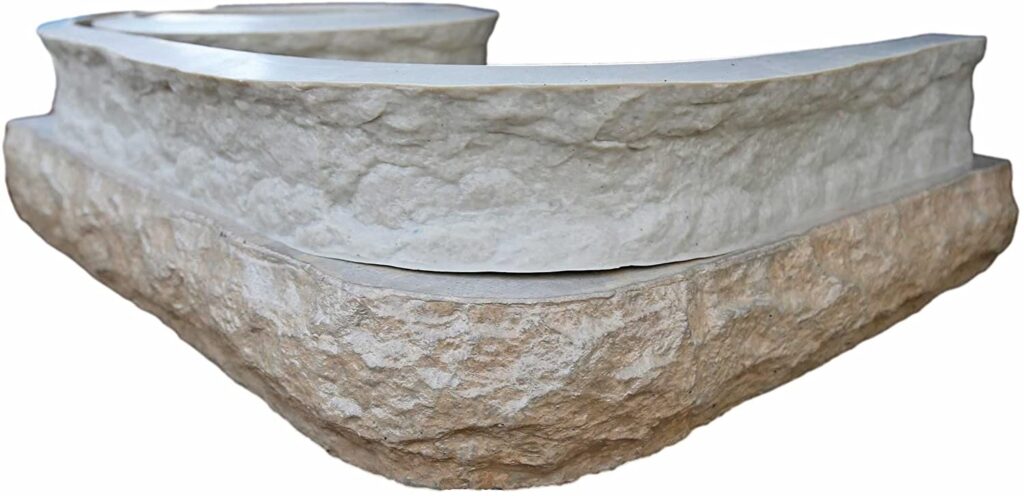

Stone Master Molds Chiseled Edge Concrete Countertop Edge Form Liner 10’L x 4″ W x 1.75″D, Recycled Material amazon.com/Stone-Master-Molds-Chiseled-Countertop

$120-140USD

amazon.com/Concrete-Countertop-Edge-Form-Standard

$36USD

Decorative Concrete Supply Source $73

amazon.com/Concrete-Countertop-Edge-Form-Chiseled

Sink Making

Modustrial mould making and sink creation. Video

Concrete Stamping

Concrete over existing concrete (Overlay) thicknesses range from 3mm (Micro topping) to 18mm, depending on the depth of the imprint.

You can stamp up to 200 square metres per day with 1.5m x 1.5m mats. Start 30-60 minutes after pouring

Seamless Travertine Concrete Stamp $260 for 1.2m x 1.2m

calicoproducts.com/product/01-concrete-stamps/seamless-stamps-skins/seamless-travertine/

Glomarble set

- 5 Pc SM 6000 Stamp Set includes

- 3 of Rigid Stamps & 1 Flexible Stamp & 1 Skin

$780USD

globmarble.com/concrete-stamps-travertine-stone-sm-6000.html

French Versailles Travertine Paver Concrete Stamp Set $630USD

globmarble.com/touch-up-joint-wheel.html $20USD

GFRC Sealing

Sealers can be divided into two general categories: densifiers or penetrating sealers and topical sealers (though there are hybrids of the two available).

Penetrating sealers or densifiers, as the name suggests, penetrates into the concrete closing the pores and strengthening it. They offer some stain resistance but greater scratch and abrasion resistance. These sealers are preferred by people who want to retain the natural beauty and feel of concrete and aren’t afraid of some staining or etching over the years.

Topical sealers are a protective layer that sits over the concrete. Topical sealers, such as acrylics, epoxies and polyurethanes offer varying degrees of stain protection depending on price, but if not cared for and applied properly are susceptible to scratching and chipping.

Counter Guard First Seal from Innovative Concrete Technologies. Lithium-based sealer is completely UV-stable and has excellent stain resistance.

Veneer Walls

Modern brick veneer installations must comply with NZS 4210:2001 Masonry construction: Materials and workmanship, which sets out the requirements for the materials and workmanship of clay, concrete and natural stone masonry. For the construction of masonry veneers, the requirements in this standard are to be used in conjunction with:

NZS 3604:2011 Timber-framed buildings

NZS 4229:2013 Concrete masonry buildings not requiring specific engineering design

Make GFRC moulds approx. 2.4m long with reversible finger joint one end and straight (Flush) the other. Apply one panel ‘Up’ and one ‘Down’ so they interlock and cover the span between upright columns (5m approx.) 10mm thick = 100Kg

Novabrik

Self-ventilated mortarless brick veneer that screws to the framing.